How Does HAWK Machinery China Co., Ltd.'s Multi-rip Saw Machine Handle Materials of Different Thicknesses?

In the ever-evolving world of flooring and panel manufacturing, precision and efficiency are paramount. As industries demand faster production rates and more versatility in material handling, the technology behind saw machines has advanced significantly. HAWK Machinery China Co., Ltd. stands at the forefront of this evolution, offering cutting-edge solutions for floor treatment, particularly through their custom 3 Rip Saw Machine designed for processing a variety of board materials, including SPC (Stone Plastic Composite), LVT (Luxury Vinyl Tile), WPC (Wood Plastic Composite), laminated panels, multi-layer solid wood, and calcium silicate.

Established in 2005, HAWK Machinery has rapidly grown into a national high-tech enterprise, with a reputation built on innovation and high-performance engineering. This esteemed company specializes in the research, development, manufacturing, sales, and service of floor treatment equipment. HAWK's impressive credentials—such as being named a Jiangsu Province Specialized and New Enterprise, a Jiangsu Province Enterprise Technology Center, and a Jiangsu Province Private Technology Enterprise—speak to the company's commitment to technological advancement and customer-centric solutions.

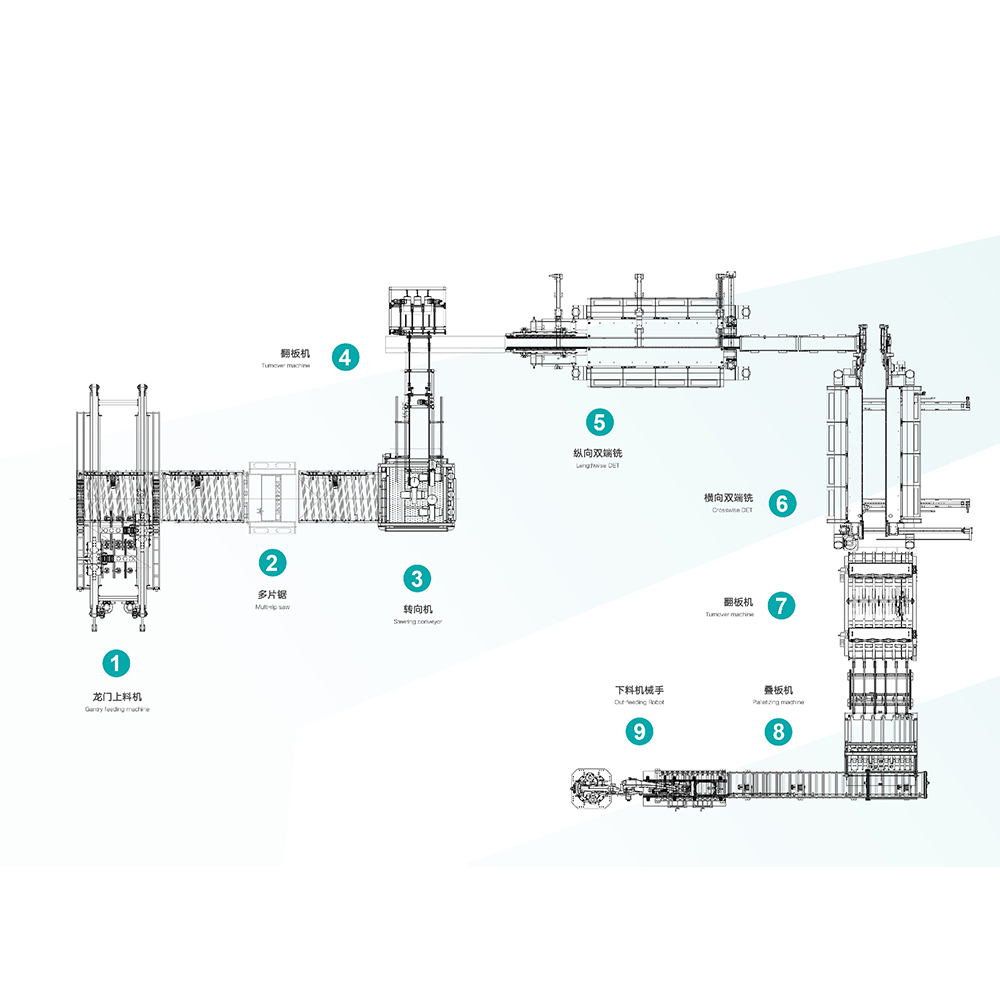

Versatility in Material Handling

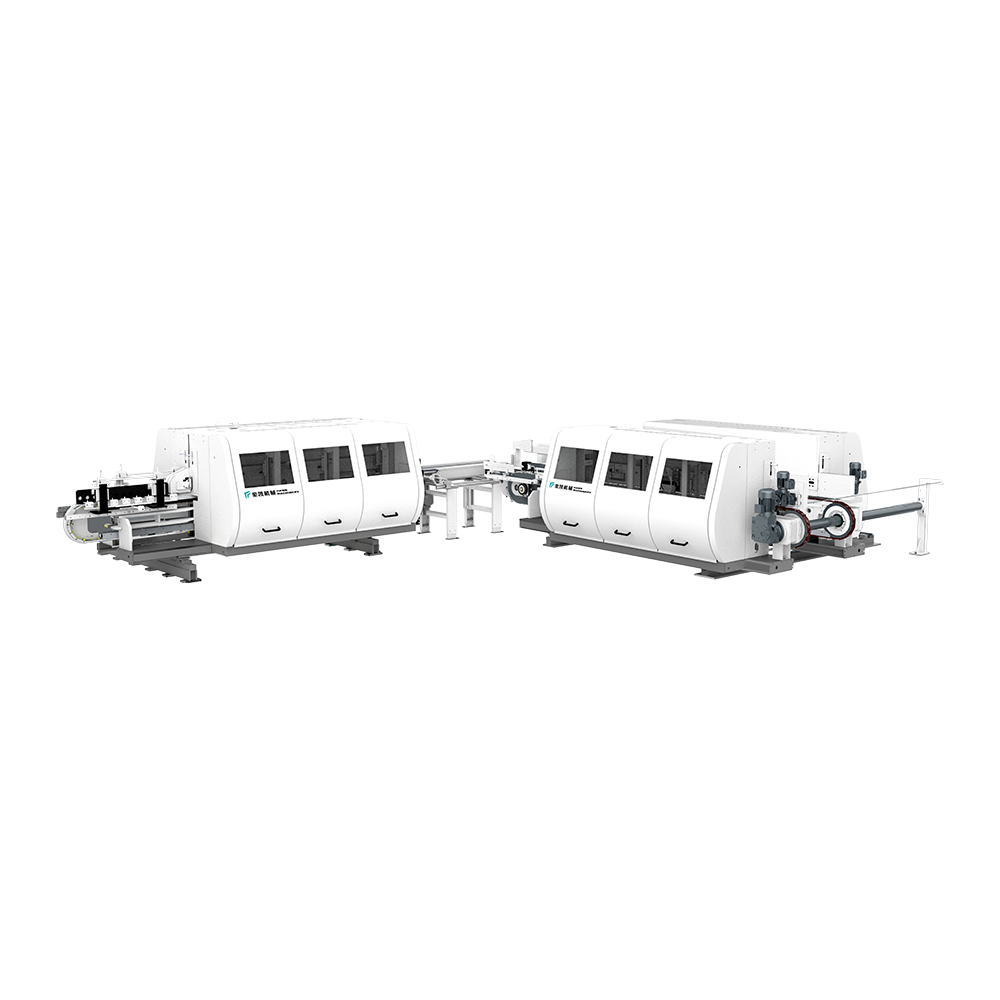

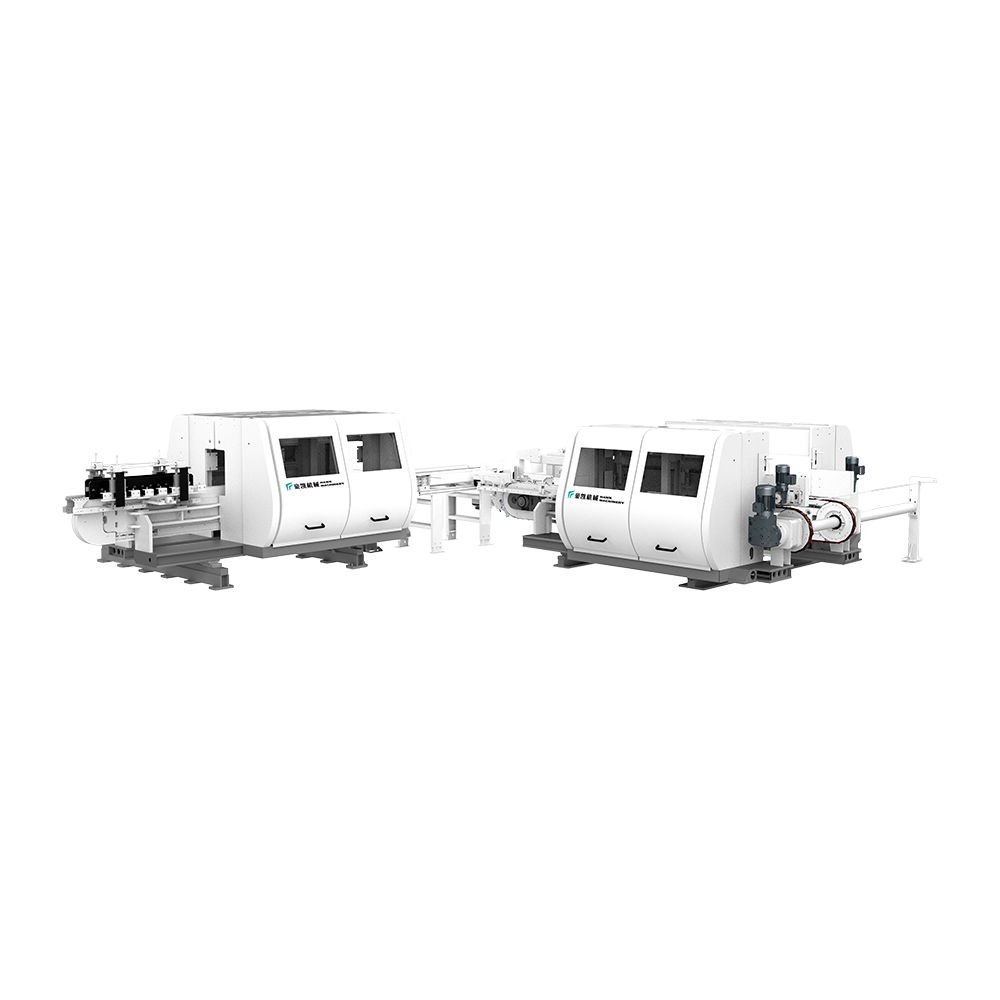

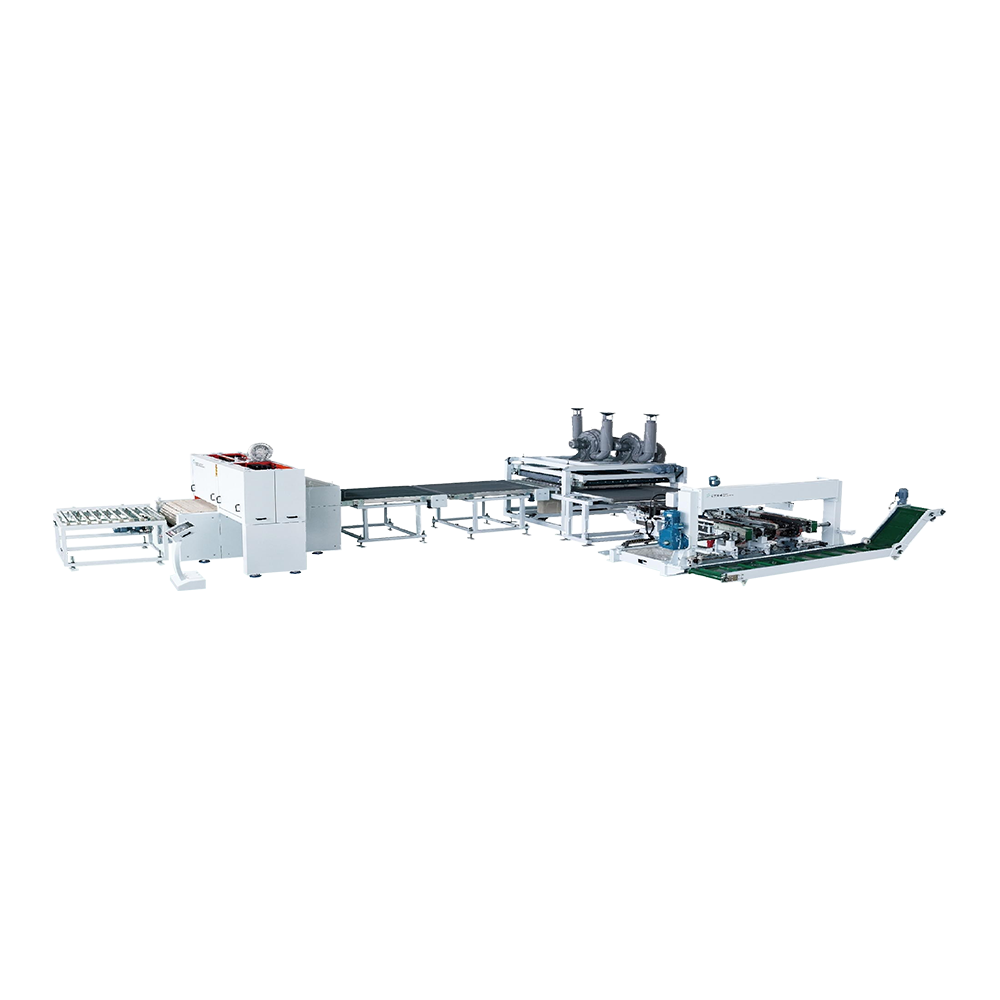

The Wall Panel Saw Machine from HAWK Machinery is engineered to handle materials with varying thicknesses, offering unmatched flexibility in production processes. Whether it’s the dense, rigid structure of multi-layer solid wood or the lighter, more flexible properties of LVT, the machine adapts to the material's specific needs with precision. The saw's cutting system accommodates board thicknesses ranging from thin laminated panels to thicker composite materials, making it ideal for diverse manufacturing requirements.

One of the key features that enables this versatility is the machine's adjustable settings, which can be fine-tuned based on material thickness. This flexibility ensures that the blade depth can be controlled to create precise cuts without causing material damage or compromising edge quality. For materials like SPC and WPC, which have a dense structure, the saw machine’s robust motor and carefully calibrated drive system maintain smooth and consistent feed speeds—up to 32 meters per minute—guaranteeing maximum throughput while preserving the integrity of the boards.

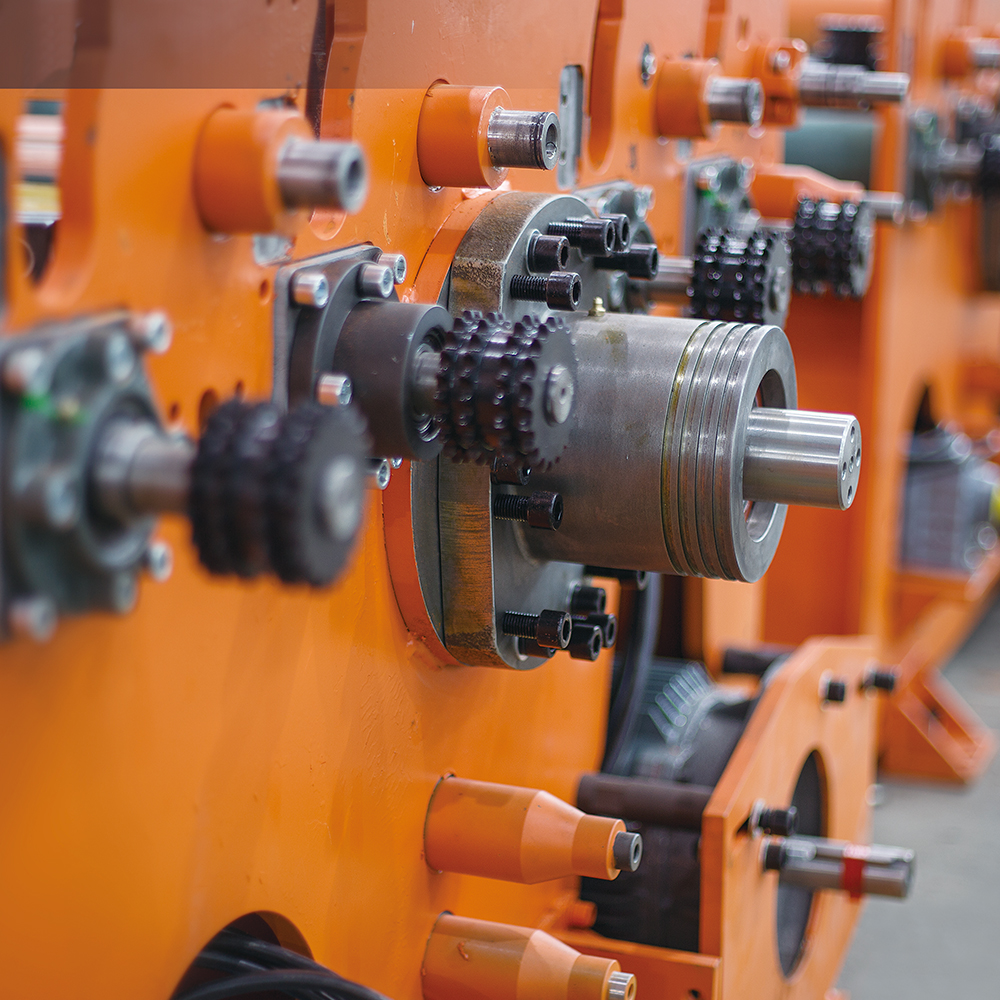

Efficient Feed and Drive Mechanism

HAWK’s SPC Floor Multi Rip Saw Machine boasts an advanced upper and lower roller drive system, a design that significantly enhances material handling. This dual-drive mechanism ensures that materials—whether rigid or flexible—are fed through the machine with minimal friction and optimal speed. With a maximum width of 1300mm, the system accommodates large panels, providing the operator with greater flexibility in production. The rollers ensure that even larger, thicker boards are moved through the system smoothly, preventing any warping or misalignment that could occur with traditional single-drive systems.

In addition, the saw’s impressive feed speed of up to 32 meters per minute allows for high-volume production, a crucial factor in industries that require both quality and quantity. This high-speed operation is particularly beneficial in applications where time is of the essence, such as large-scale flooring or wall panel production.

Customizable Solutions for Specific Needs

HAWK Machinery understands that every customer has unique requirements. Whether the need is for cutting thicker, tougher materials or creating ultra-precise cuts in thinner boards, the company offers customizable solutions to meet a variety of specifications. Their ability to tailor the Engineered Floor Multi Rip Saw Machine for specific projects ensures that businesses can achieve the exact results they desire, no matter the material thickness.

This level of customization is not just about adjusting technical settings—it extends to the overall machine configuration. With each saw machine designed to meet the needs of industries such as flooring, construction, and interior design, HAWK’s engineering team works closely with clients to ensure their exact specifications are met. This approach not only enhances operational efficiency but also reduces waste, ensuring that every cut is made with purpose and precision.

Uncompromising Quality and Precision

HAWK Machinery’s commitment to excellence extends beyond just raw performance—it is embedded in the craftsmanship and engineering that go into every Solid Parquet Floor Multi Rip Saw Machine. The precise manufacturing process ensures that every machine is equipped to handle the most challenging materials with ease. The integration of cutting-edge technology and high-quality components allows for superior cutting performance, whether dealing with the flexibility of laminated panels or the rigidity of multi-layered wood.

HAWK’s machines are not only built to meet high standards but are also designed with long-term durability in mind. The company’s focus on reliability ensures that businesses can count on their machines to deliver consistent, high-quality results year after year.

The ability to handle materials of various thicknesses with ease and precision makes HAWK Machinery China Co., Ltd.’s Multi-rip Saw Machine an indispensable asset to the flooring and panel manufacturing industry. With its robust design, flexible configuration options, and superior performance, HAWK’s Multi-rip Saw is more than just a tool—it is a catalyst for efficiency, quality, and innovation. As industries demand faster, more efficient solutions, HAWK continues to lead the way, offering customizable, high-tech equipment that meets the needs of today’s competitive market.

For businesses that require top-tier cutting performance, HAWK Machinery’s Multi-rip Saw Machine offers an unrivaled combination of versatility, precision, and durability, ensuring the highest level of productivity and material handling.