Super Purchasing for Full Automatic Deck Machine - Double End Tenoner Line with Double L Chain for Herringbone floor – Hawk

Super Purchasing for Full Automatic Deck Machine - Double End Tenoner Line with Double L Chain for Herringbone floor – Hawk Detail:

| Model | Portrait HKL226 | Horizontal HKL227 |

| The maximum number of axes that can be loaded | 6+6 | 6+6 |

| Feed rate (m/min) | 60 | 30 |

| Minimum workpiece width (mm) | 70 | – |

| Maximum workpiece width (mm) | 400 | – |

| Minimum workpiece length (mm) | 400 | 400 |

| Maximum workpiece length (mm) | – | 1600/2500 |

| Floor thickness (mm) | 8-25 | 8-25 |

| Tool Diameter (mm) | φ250-285 | φ250-285 |

| Working height (mm) | 1100 | 980 |

| Dimensions (mm) | 5200*3000*2000 | 5200*3800*1900 |

| Machine weight (mm) | 7 | 7 |

This series of equipment is reasonable in design and is mainly used in the production of multi-layer flooring, bamboo flooring and bamboo-wood composite flooring. You can paint first and then open the groove without damaging the floor surface. It has the characteristics of large processing width, simple

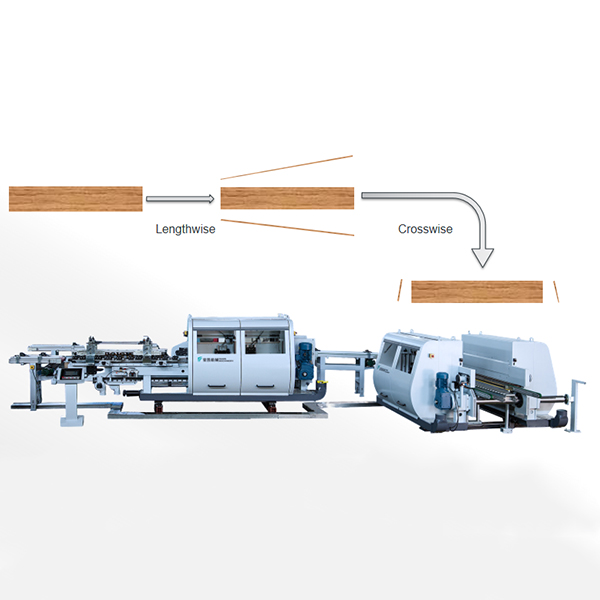

Hawk Machinery High Speed DET Line with double L shape Chain, using the latest international technology, after years of technical upgrading, with more than 300 customers at domestic and abroad use certification, suitable for narrow PVC floor, laminate floor, solid wood multi layer floor, bamboo floor, SPC floor and other types of plate slotting processing. Hawk Machinery High Speed DET Line with double L shape Chain can let the plank do paint first, then do the slotting work and do not damage the floor surface, can satisfy especially the floor processing production of all sorts of narrow type, has wide adaptability, adjust concise and fast, stability is good, the advantage of processing precision is higher.

Hawk Machinery High Speed DET Line with double L shape Chain, is a machine especially for the Herringbone parquet floor in the series of Hawk Machinery high speed slotting line. The long side end and the short side end of the slotting line are equipped with 3 hatches and a total of 6 working positions. The long side of the feeding bin can be extended, so that the longer plate feeding can be more stable. The transmission chain adopts double L shape chain design, and the guide rail is an integral guide rail to meet the processing sizes and specifications of various plates, and to ensure the stability of production and processing accuracy. In order to improve the accuracy of processing, in alignment with the position of the milling cutter using built-in pneumatic pressure plate device, the adjustment is simple and fast, and will not damage the surface of the floor, so that the floor assembly is more seamless.

Hawk Machinery High Speed DET Line with double L shape Chain with competitive price and high quality, high efficiency, good stability. Hawk Machinery High Speed DET Line with double L shape Chain is the best choice for your processing of narrow and Herringbone PVC floor, laminate floor, solid wood multi layer floor, bamboo floor, SPC floor, and other types of boards

Product detail pictures:

Related Product Guide:

We insist on offering high-quality creation with superior business enterprise concept, honest revenue plus the greatest and fast service. it will bring you not only the high quality solution and huge profit, but essentially the most significant is usually to occupy the endless market for Super Purchasing for Full Automatic Deck Machine - Double End Tenoner Line with Double L Chain for Herringbone floor – Hawk , The product will supply to all over the world, such as: Portland, Cannes, Slovak Republic, They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a really should in your case of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we've been planning to possess a vibrant prospect and to be distributed all over the world within the years to come.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.