professional factory for Building Material Extruder Machine - 2 Door High Speed Floor Trimming Slotting Line – Hawk

professional factory for Building Material Extruder Machine - 2 Door High Speed Floor Trimming Slotting Line – Hawk Detail:

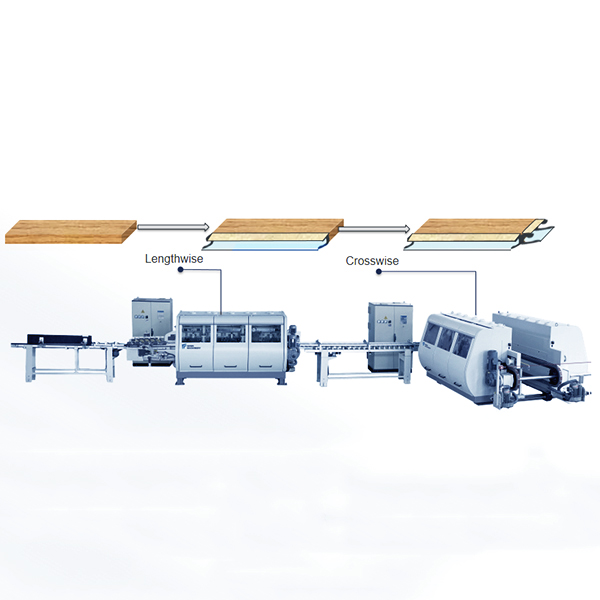

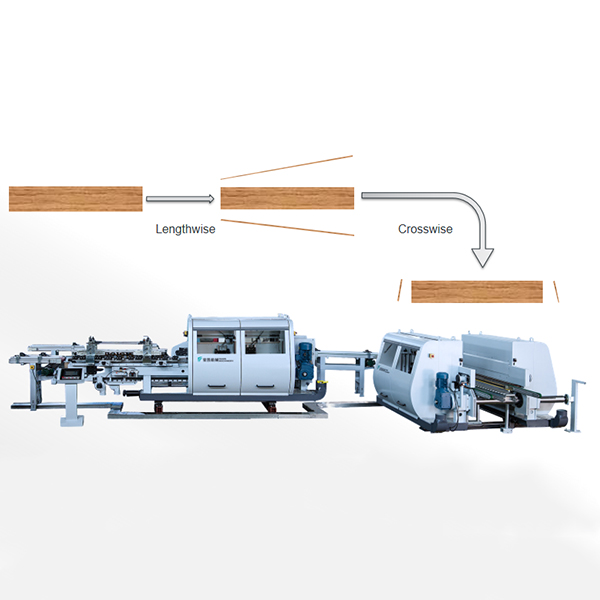

| Lengthwise | Crosswise | |

| Type | HKH326G | HKH323G |

| Max.Spindles | 4+4 | 4+4 |

| Feeding Speed (m/min) | 5-100 | 5-40 |

| Min.width of workpieces (mm) | 130/110 | – |

| Max.width of workpieces (mm) | 600 | – |

| Min.Length of workpieces (mm) | 450 | 400 |

| Max.Length of workpieces (mm) | – | 1600/2500 |

| Thickness of workpieces (mm) | 1.5-8 | 1.5-8 |

| Diameter of cutter (mm) | Φ250-285 | Φ250-285 |

| Working height (mm) | 1100 | 980 |

| Dimensions (mm) | 5200*3000*2000 | 5200*3800*1900 |

| Machine weight (T) | 7.5 | 7.5 |

The Hawk Machinery High Speed Double End Trimming & Chamfering Line adopts the international advanced technology, after years of technical upgrading, more than 100 customers confirmation of using, with the feature of fast speed, high processing accuracy, and stable capacity, very suitable for PVC, LVT, Dry back SPC and other less thickness plate trimming and chamfering.

The Hawk Machinery High Speed Double End Trimming & Chamfering Line has lengthwise side and crosswise side, each side is equipped with 2 hatches and each side with 4 working positions. The feeding part can be extended, so that the longer plate feeding will be more stable. The transmission chain adopts double wide chain design, and the guide rail is an integral guide rail to meet the processing sizes and specifications of various plates, and to ensure the stability of production and processing accuracy. The chains are also available in L- shape chains and double narrow chains so that can accommodate the production of narrower floors (Herringbone parquet).

The Hawk Machinery High Speed Double End Trimming & Chamfering Line is equipped with specialized upper and lower slide plate, the adjustment is simple and fast, can effectively improve the processing accuracy, and the floor surface will not cause indentation.

The Hawk Machinery High Speed Double End Trimming & Chamfering Line has high quality, high efficiency, good stability, is your best choice for processing PVC, LVT, Dry back SPC and other less thickness sheet material.

Product detail pictures:

Related Product Guide:

Our group through specialist training. Skilled expert knowledge, sturdy sense of assistance, to fulfill the provider needs of shoppers for professional factory for Building Material Extruder Machine - 2 Door High Speed Floor Trimming Slotting Line – Hawk , The product will supply to all over the world, such as: Luxembourg, Mozambique, Surabaya, We supply skilled service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound items with good logistics service and economical cost. Depending on this, our products and solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ??customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.