OEM Customized Contact Card Punching Machine - 4-door double-ended milling groove – Hawk

OEM Customized Contact Card Punching Machine - 4-door double-ended milling groove – Hawk Detail:

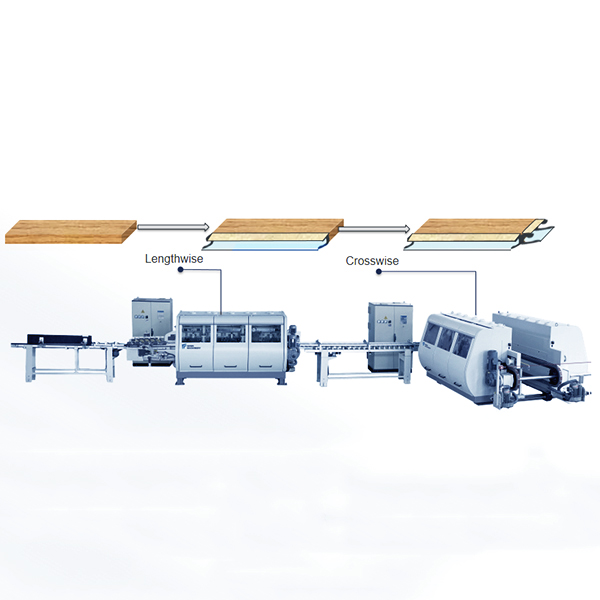

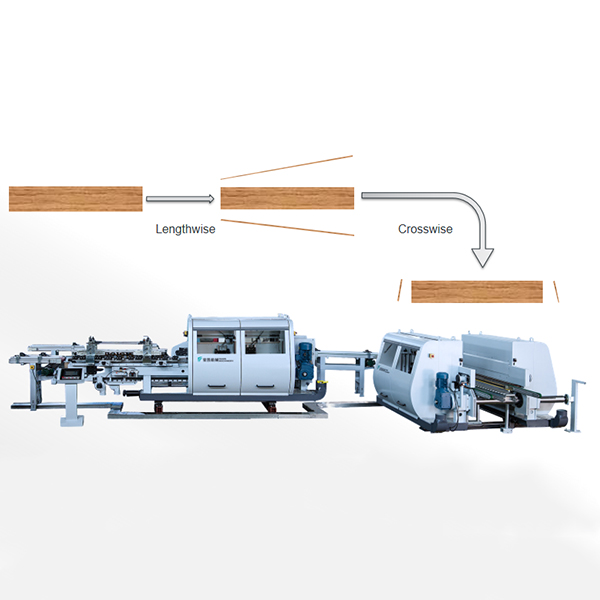

This equipment has a long body, high-speed design, and a separate compartment. It can be equipped with special equipment such as online painting and thermal transfer according to customers’ requirements. It is more stable for super long floor processing and improves machining accuracy.

| Model | Portrait HKS336 | Landscape HKH347 |

| The maximum number of axes that can be loaded | 6+6 | 7+7 |

| Feed rate (m/min) | 120 | 60 |

| Minimum workpiece width (mm) | 95 | – |

| Maximum workpiece width (mm) | 270 | – |

| Minimum workpiece length (mm) | 400 | 400 |

| Maximum workpiece length (mm) | – | 1600/2500 |

| Floor thickness (mm) | 8-25 | 8-25 |

| Tool Diameter (mm) | φ250-285 | φ250-285 |

| Working height (mm) | 1080 | 980 |

| Dimensions (mm) | 6200*2100*2000 | 5200*3800*1900 |

| Machine weight (mm) | 9 | 10 |

Product detail pictures:

Related Product Guide:

Our staff through skilled training. Skilled skilled knowledge, potent sense of company, to satisfy the provider requirements of consumers for OEM Customized Contact Card Punching Machine - 4-door double-ended milling groove – Hawk , The product will supply to all over the world, such as: Luxembourg, Durban, Netherlands, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!

Write your message here and send it to us