OEM China Ledgestone Production Line - Semi – automatic connection of split saws – Hawk

OEM China Ledgestone Production Line - Semi – automatic connection of split saws – Hawk Detail:

| Total power | 65KW |

| Total vacuum | 22000m3/h |

| Vacuuming wind speed | 32m/s |

| Sawing thickness | 3-25mm |

| Speed | 8 pieces / minute |

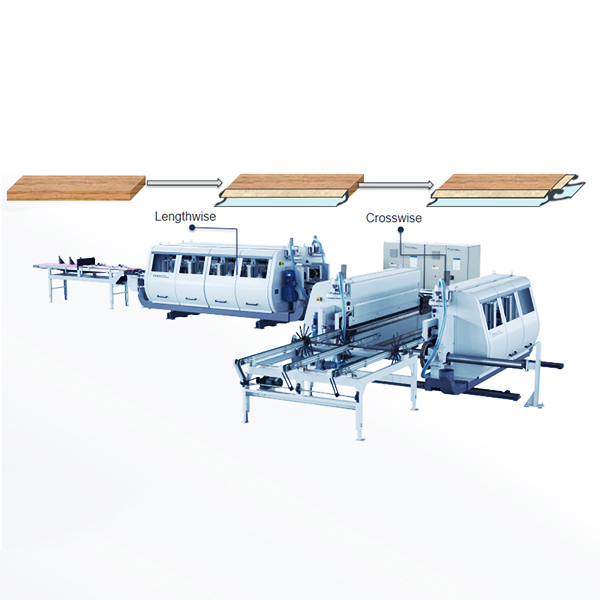

The Hawk Machinery Semi-automatic Cutting line is suitable for cutting and processing of various specifications of solid wood multi-layer floor, bamboo wood floor, laminate floor, SPC floor and other material floors. It has the characteristics of high precision, fast speed and stable operation, and is suitable for all kinds of plates and specifications.

The Hawk Machinery Semi-automatic Cutting line is composed of hydraulic manual feeding table, three rip saw feeding roller conveyor, three rip saw, three rip saw discharging roller conveyor, steering conveyor, multi rip saw feeding roller conveyor, multi rip saw, multi rip saw discharging roller conveyor, steering conveyor and blanking roller conveyor. The plates are manually fed into the three rip saw feeding roller conveyor, and then enter the three rip saw for central cutting and fixed length edge cutting. After the three rip saw, they enter the multi rip saw through the discharge drum conveyor and steering conveyor, cut the large plate into small pieces according to the specification requirements, and then discharge the plank manually.

The Hawk Machinery Semi-automatic Cutting line’s technology is advanced, which is designed by 3D software and processed by CNC machining center. The machine has high precision and good cutting straightness, which can meet the requirements of all kinds of wood floors. The cutting of general reinforced composite floors can not only achieve the effect of straight seam and material saving, but also reduce the number of workers and improve production efficiency. The operation is simple. The spacing between the upper and lower pressing rollers is adjusted according to the floor thickness. The adjustment of the pressing roller can be completed by shaking the adjustment handle. The whole machine is completely closed, the generated dust is directly discharged through the dust removal system, and the working environment is clean.

The Hawk Machinery Semi-automatic Cutting line has reasonable design, compact structure and high precision. Reduce labor intensity, save space, labor, energy consumption, and greatly improve labor efficiency.

Product detail pictures:

Related Product Guide:

We also offer product sourcing and flight consolidation services. We've got our personal factory and sourcing office. We can easily present you with almost every style of merchandise linked to our merchandise range for OEM China Ledgestone Production Line - Semi – automatic connection of split saws – Hawk , The product will supply to all over the world, such as: Bandung, Belarus, Bahamas, With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we are trying our best to be your good partner.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.