Factory wholesale Flat Bag Making Machine - Hawk Machinery Multi Rip Saw – Hawk

Factory wholesale Flat Bag Making Machine - Hawk Machinery Multi Rip Saw – Hawk Detail:

| Main motor power: | 18.5KW |

| Feed motor: | 1.5KW |

| Maximum speed: | 3200(r/min) |

| Saw blade specification: | 300mmX3.2mmX2.2mmX(80-100)mm |

| Saw speed: | Adjustable 15~35(m/min) |

| Sheet straightness: | < 0.2mm/m |

| Saw blade diameter: | Ф80~Ф100mm |

| Sawing thickness: | 3-25mm |

| Dimensions: | Length 2.2X Width 1.9X Height 1.2 (m) |

| Weight: | 2.6(T) |

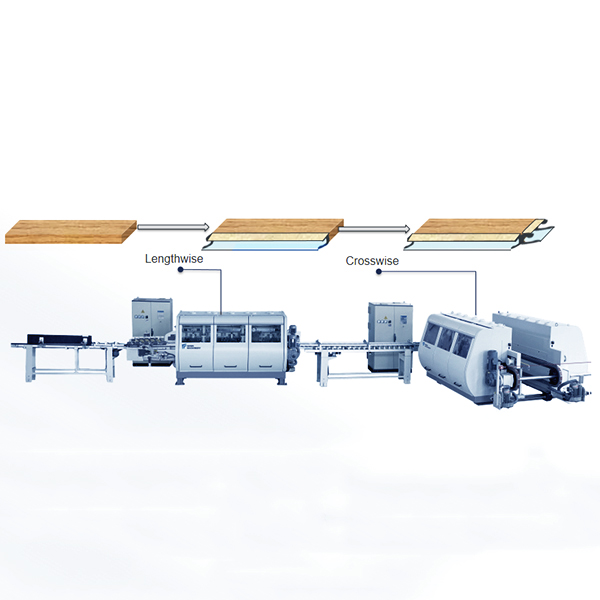

The machine is composed of a fully enclosed body and a feeding and discharging platform. The saw blade is directly mounted on the main shaft of the motor, the feeding mechanism is driven by the adjustable variable speed motor, and the feeding drive roller can be adjusted together, the whole machine has compact structure and advanced design.

Main features:

1, advanced technology, the use of THREE-DIMENSIONAL software design, large gantry processing center, in the domestic leading level;

2, high precision, saw seam straightness is good, can meet the requirements of imitation wood floor, for general laminate flooring and SPC floor sawing can achieve good straightness, material saving effect;

3, environmental protection, the whole machine is completely closed, the dust produced is directly discharged through the dust discharge system, the working environment is clean.

Technical parameters:

1. Floor size:

- maximum width: 1300 mm.

- thickness: 6-20 mm.

2. Basic equipment description:

- high precision chrome plated spindle with spindle diameter of 80 mm and double bond;The spindle diameter is 100 mm when hydraulic shaft sleeve is used.

- spindle motor 18.5 kw.

- the upper press roller is a rubber roller, and the lower roller is a hard chromium steel roller.

- internal surface dust removal device.

- saw blade cutting, anti – beating and tightening device.

- central vacuuming device.

3. Production line speed:

-25 -35 m/min.

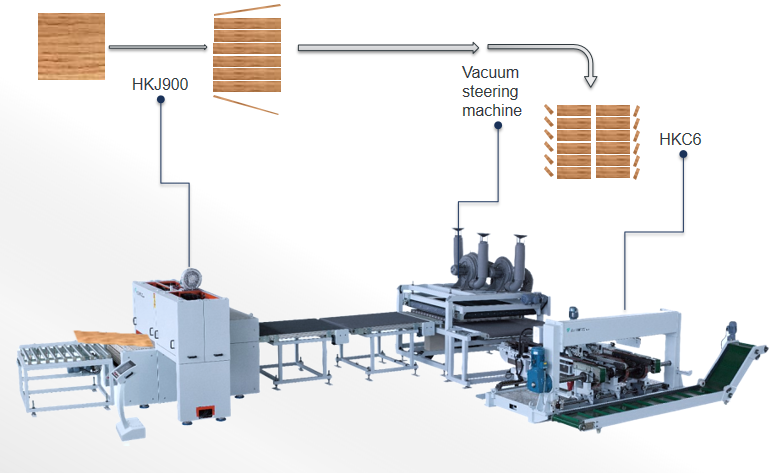

The Hawk High Performance Auto Cutting Line is combined with HKJ900 Multi Rip Saw, Vacuum Steering Machine and HKC6 Cross Cut saw. The Hawk High Performance Auto Cutting Line is suitable for high-speed, accurate slicing and aligning of large plates, and more suitable for the less thickness material like dryback SPC floor and LVT floor instead of punch machine. The innovative saw blade of the HKJ900 moving out and independent adjusting device realizes the quick replacement of saw blade and the quick conversion of floor specification. The automatic production connection mode can realize the cutting speed of 40 meters per minute and significantly reduce the production cost

The Hawk High Performance Auto Cutting Line:

1. High efficiency, the speed is 15-18 pcs / min.

2.High precision, the straightness of panel controlled within 0.05-0.10mm/m.

3.Separate structure for saw blade and motor, so it can quickly and easily switch various product specifications.

4.Touch screen sets, the servo motor control the movement of saw blade, easy operation, high precision.

5.Cutting mould doesn’t need, it can save cost and settling time.

6.Cut the products which punch press can’t process(Includes specific products caused by thickness, length and hardness).

7.Batch process, less area occupation.

8.Realize automation of continuous product, reduce the number of employment.

| HKJ900 | HKC6 | |

| Spindle motor power | 5.5kw | 4.0kw |

| Saw blade motor power | 8*5.0kw | 3*5.0kw |

| Saw blade motor speed | 2500 – 5200rpm (Frequency conversion) | 2500 – 5200rpm (Frequency conversion) |

| Saw blade spacing adjustment mode | Touch screen digital adjustment | Touch screen digital adjustment |

| Saw blade spacing adjustment accuracy | ±0.015mm | ±0.015mm |

| Saw blade diameter | 300 – 320mm | 300 – 320mm |

| Diameter of hole inside saw blade | 140mm | 140mm |

| Saw blade thickness | 1.8 – 3mm | 1.8 – 3mm |

| Adjusting range of saw blade lifting | -10 – 70mm (Take the working plane as the reference) | – |

| Saw blade lifting adjustment mode | Touch screen digital adjustment | – |

| Sawing plate speed | 5 – 40m/min (Frequency conversion) | 5 – 40m/min (Frequency conversion) |

| Sawing plate thickness | 2 – 20mm | 2 – 20mm |

| Maximum width of saw plate | 1350mm | 600mm |

| Saw plate length range | 500 – 2400mm | 2400mm |

| Gross weight of equipment | ≈5.5T | ≈3.5T |

Product detail pictures:

Related Product Guide:

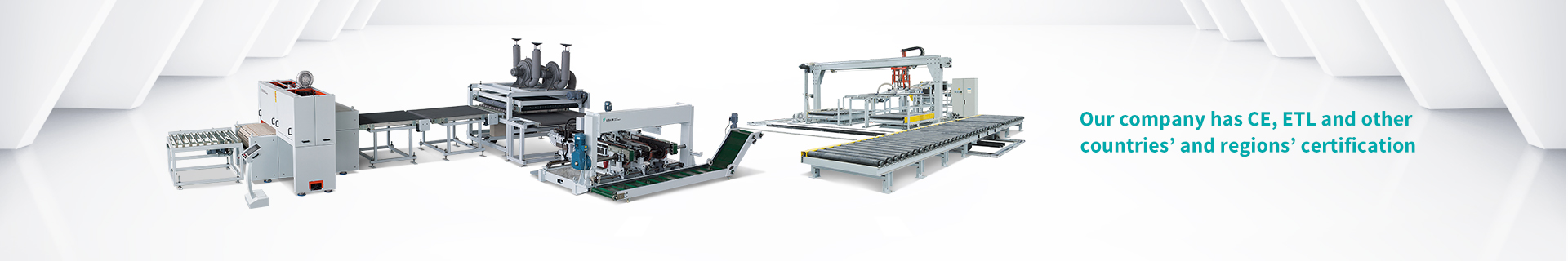

Our company has been concentrating on brand strategy. Customers' pleasure is our greatest advertising. We also source OEM service for Factory wholesale Flat Bag Making Machine - Hawk Machinery Multi Rip Saw – Hawk , The product will supply to all over the world, such as: Atlanta, Belgium, Turkey, Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.