Factory directly Roof Machine Roll Forming - 3 Door High Speed Floor Slotting Machine – Hawk

Factory directly Roof Machine Roll Forming - 3 Door High Speed Floor Slotting Machine – Hawk Detail:

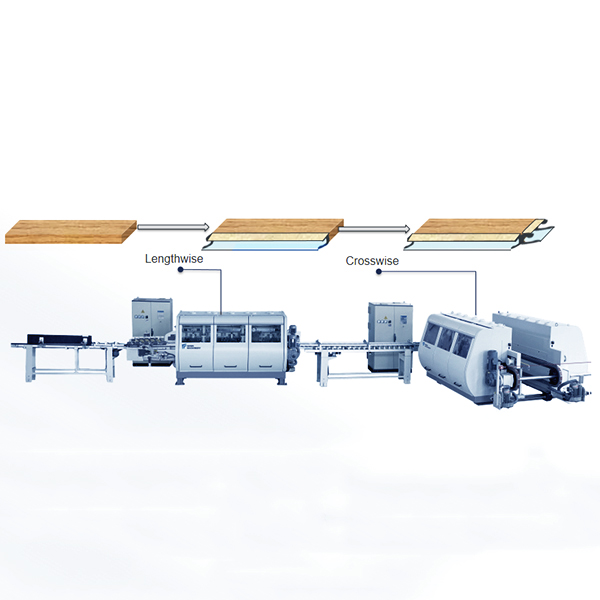

| Lengthwise | Crosswise | |

| Working Position | 6+6 | 6+6 |

| Speed(m/min) | 30-120 | 15-60 |

| Min.Width(mm) | 90 | – |

| Max.Width (mm) | 400 | – |

| Min.Length (mm) | 400 | 400 |

| Max.Length(mm) | – | 1600/2500 |

| Thickness (mm) | 4-25 | 4-25 |

| Cutter Dia (mm) | φ250-285 | φ250-285 |

| Working H (mm) | 1100 | 980 |

| Machine Size (mm) | 5200*3000*2000 | 5200*3800*1900 |

| Machine Weight (kgs) | 9500 | 9500 |

Hawk Machinery 3 Door High Speed Floor Slotting Machine Line, using the latest international technology, after years of technical upgrading, with more than 600 customers at domestic and abroad use certification, suitable for PVC floor, laminate floor, solid wood multi layer floor, bamboo floor, SPC floor, calcium silicate board, SMC plate and other types of plate slotting processing. Hawk Machinery 3 Door High Speed Floor Slotting Machine Line can let the plank do paint first, then do the slotting work and do not damage floor surface, can satisfy especially the floor processing production of all sorts of buckle type, have adaptability wide, adjust concise and fast, stability is good, the advantage of processing precision is higher.

Hawk Machinery 3 Door High Speed Floor Slotting Machine Line, is the most classic configuration of our hawk machinery slotting line. The long side end and the short side end of the production line are equipped with 3 hatches, a total of 6 working positions for each side, the long side of the feeding bin can be extended, so that the longer plate feeding can be more stable. The transmission chain adopts double wide chain design, and the guide rail is an integral guide rail to meet the processing sizes and specifications of various plates, and to ensure the stability of production and processing accuracy. In order to improve the accuracy of processing, in alignment with the position of the milling cutter using built-in pneumatic pressure plate device, the adjustment is simple and fast, and will not damage the surface of the floor, so that the floor assembly is more seamless.

Hawk Machinery 3 Door High Speed Floor Slotting Machine Line with competitive price and high quality, high efficiency, good stability. Hawk Machinery 3 Door High Speed Floor Slotting Machine Line is the best choice for your processing OF PVC floor, laminate floor, solid wood multi layer floor, bamboo floor, SPC floor, calcium silicate board, insulation board and other types of boards

Product detail pictures:

Related Product Guide:

We have now sophisticated machines. Our solutions are exported to the USA, the UK and so on, enjoying a great reputation amid consumers for Factory directly Roof Machine Roll Forming - 3 Door High Speed Floor Slotting Machine – Hawk , The product will supply to all over the world, such as: Sri Lanka, Slovakia, Sri Lanka, Abiding by our motto of "Hold well the quality and services, Customers Satisfaction", So we provide our clients with high quality products and excellent service. Please feel free to contact us for further information.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.