Factory best selling Injection Blow Moulding Machine - Double End Tenoner Line with Double L Chain for Herringbone floor – Hawk

Factory best selling Injection Blow Moulding Machine - Double End Tenoner Line with Double L Chain for Herringbone floor – Hawk Detail:

| Model | Portrait HKL226 | Horizontal HKL227 |

| The maximum number of axes that can be loaded | 6+6 | 6+6 |

| Feed rate (m/min) | 60 | 30 |

| Minimum workpiece width (mm) | 70 | – |

| Maximum workpiece width (mm) | 400 | – |

| Minimum workpiece length (mm) | 400 | 400 |

| Maximum workpiece length (mm) | – | 1600/2500 |

| Floor thickness (mm) | 8-25 | 8-25 |

| Tool Diameter (mm) | φ250-285 | φ250-285 |

| Working height (mm) | 1100 | 980 |

| Dimensions (mm) | 5200*3000*2000 | 5200*3800*1900 |

| Machine weight (mm) | 7 | 7 |

This series of equipment is reasonable in design and is mainly used in the production of multi-layer flooring, bamboo flooring and bamboo-wood composite flooring. You can paint first and then open the groove without damaging the floor surface. It has the characteristics of large processing width, simple

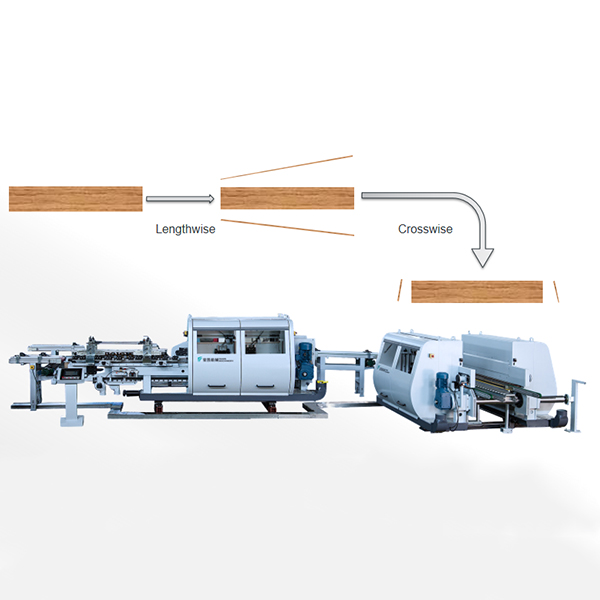

Hawk Machinery High Speed DET Line with double L shape Chain, using the latest international technology, after years of technical upgrading, with more than 300 customers at domestic and abroad use certification, suitable for narrow PVC floor, laminate floor, solid wood multi layer floor, bamboo floor, SPC floor and other types of plate slotting processing. Hawk Machinery High Speed DET Line with double L shape Chain can let the plank do paint first, then do the slotting work and do not damage the floor surface, can satisfy especially the floor processing production of all sorts of narrow type, has wide adaptability, adjust concise and fast, stability is good, the advantage of processing precision is higher.

Hawk Machinery High Speed DET Line with double L shape Chain, is a machine especially for the Herringbone parquet floor in the series of Hawk Machinery high speed slotting line. The long side end and the short side end of the slotting line are equipped with 3 hatches and a total of 6 working positions. The long side of the feeding bin can be extended, so that the longer plate feeding can be more stable. The transmission chain adopts double L shape chain design, and the guide rail is an integral guide rail to meet the processing sizes and specifications of various plates, and to ensure the stability of production and processing accuracy. In order to improve the accuracy of processing, in alignment with the position of the milling cutter using built-in pneumatic pressure plate device, the adjustment is simple and fast, and will not damage the surface of the floor, so that the floor assembly is more seamless.

Hawk Machinery High Speed DET Line with double L shape Chain with competitive price and high quality, high efficiency, good stability. Hawk Machinery High Speed DET Line with double L shape Chain is the best choice for your processing of narrow and Herringbone PVC floor, laminate floor, solid wood multi layer floor, bamboo floor, SPC floor, and other types of boards

Product detail pictures:

Related Product Guide:

With responsible good quality method, good status and excellent client services, the series of solutions produced by our company are exported to lots of countries and regions for Factory best selling Injection Blow Moulding Machine - Double End Tenoner Line with Double L Chain for Herringbone floor – Hawk , The product will supply to all over the world, such as: Slovakia, Denmark, Australia, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, please feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our products, please feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.