China Factory for Concrete Slotting Grooving Machine - 4 door High Speed Floor Slotting Machine – Hawk

China Factory for Concrete Slotting Grooving Machine - 4 door High Speed Floor Slotting Machine – Hawk Detail:

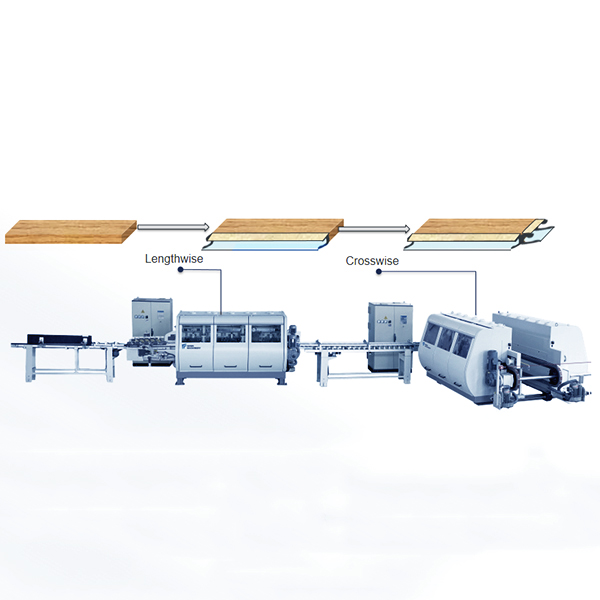

| Lengthwise | Crosswise | ||

| Working Positons | HKHS46G 8+8 | HKH447G 8+8 | |

| Speed | (m/min) | 5-100 | 5-40 |

| Min.Width | (mm) | 120 | |

| Max.Width | (mm) | 400 | |

| Min.Length | (mm) | 400 | 400 |

| Max.Length | (mm) | 1600/2500 | |

| Thichness | (mm) | 3-25 | 3-25 |

| Cutter Dia. | (mm) | 250-285 | 250-285 |

| Working H | (mm) | 1100 | 980 |

| Size | (mm) | 7200×3000×2000 | 7200×3800×1900 |

| Weight | (T) | 12 | 12 |

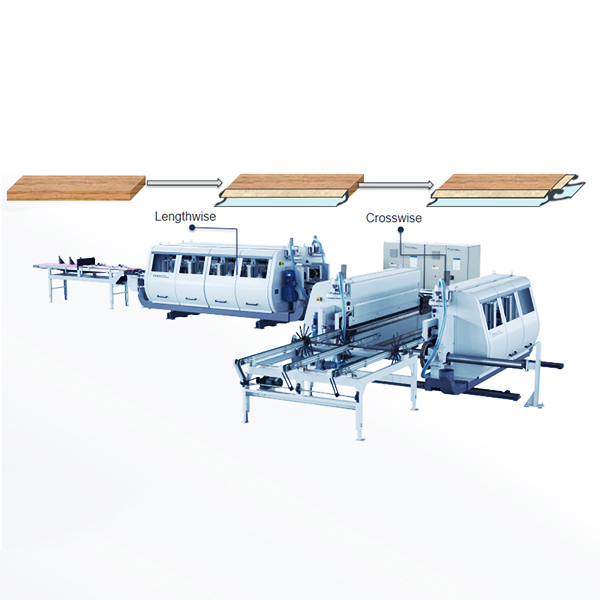

Hawk Machinery 4 Door High Speed Floor Slotting Machine Line, using the latest international technology, after years of technical upgrading, with more than 600 customers at domestic and abroad use certification, suitable for PVC floor, laminate floor, solid wood multi layer floor, bamboo floor, SPC floor, calcium silicate board, SMC plate and other types of plate slotting processing. Hawk Machinery 4 Door High Speed Floor Slotting Machine Line can let the plank do paint first, then do the slotting work and do not damage floor surface, can satisfy especially the floor processing production of all sorts of buckle type, have adaptability wide, adjust concise and fast, stability is good, the advantage of processing precision is higher.

Hawk Machinery 4 Door High Speed Floor Slotting Machine Line, is the Hawk Machinery slotting line’s upgrade configuration relative to the 3 door slotting machine line. The long side end and the short side end of the slotting line are equipped with 4 hatches and a total of 8 working positions. Because there are two more stations than the 3 doors machine, the production speed is faster and the tool wear is less relative to the time. the long side of the feeding bin can be extended, so that the longer plate feeding can be more stable. The transmission chain adopts double wide chain design, and the guide rail is an integral guide rail to meet the processing sizes and specifications of various plates, and to ensure the stability of production and processing accuracy. In order to improve the accuracy of processing, in alignment with the position of the milling cutter using built-in pneumatic pressure plate device, the adjustment is simple and fast, and will not damage the surface of the floor, so that the floor assembly is more seamless.

Hawk Machinery 4 Door High Speed Floor Slotting Machine Line with competitive price and high quality, high efficiency, good stability. Hawk Machinery 4 Door High Speed Floor Slotting Machine Line is the best choice for your processing OF PVC floor, laminate floor, solid wood multi layer floor, bamboo floor, SPC floor, calcium silicate board, insulation board and other types of boards

Product detail pictures:

Related Product Guide:

Well-run equipment, professional sales team, and better after-sales services; We are also a unified big family, everyone stick to the company value "unification, dedication, tolerance" for China Factory for Concrete Slotting Grooving Machine - 4 door High Speed Floor Slotting Machine – Hawk , The product will supply to all over the world, such as: Zurich, Italy, Lesotho, Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.